CNC Programmer

&

CNC Operator Training

Unlock the Full Potential of Your Production with Expert-Led CNC Training💡

At MGC Technical Services Ltd, we are specialists in the CNC area 🤖, providing comprehensive solutions and application support across the entire United Kingdom and Europe 🌍. Headquartered in Aberdeen, our mission is to empower your workforce with the precise skills needed to excel in modern manufacturing.🏭 Whether you're starting new production lines, optimising existing workflows ⚙️, or seeking to upskill your team 📈, our flexible, industry-focused programs for CNC Operators and Programmers are designed for rapid skill mastery and tangible results.✨

Our Unique Training Advantage: 70% Hands-On Practical Learning 🛠️

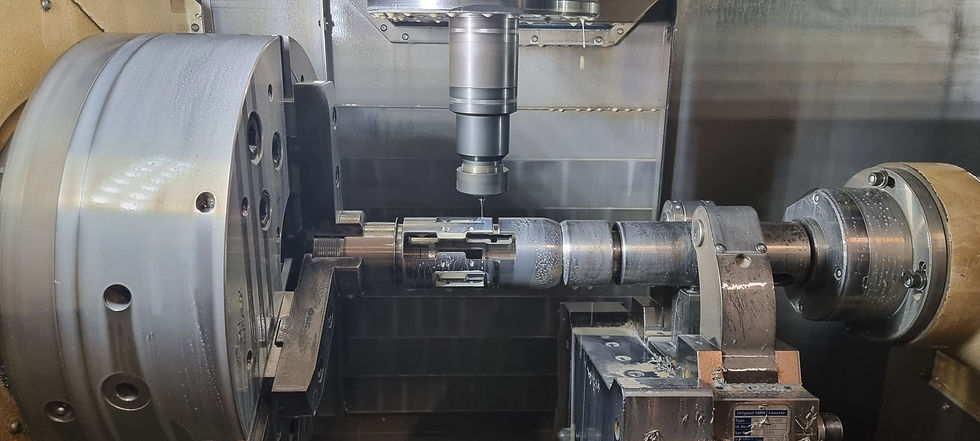

We firmly believe that the most effective way to learn CNC is by doing. That's why our training methodology prioritises 70% hands-on practical training on CNC controls, complemented by 30% classroom theory 🧑🏫. This approach ensures participants not only understand the concepts but can immediately apply them in a real-world setting.📈

Why Choose MGC Technical Services Ltd for Your

CNC Training? 👇

✅ Practical Focus (70% Hands-On): Our core philosophy ensures rapid skill acquisition and confidence through extensive machine or simulator interaction. 🎯

✅ Tailored to Your Needs: All courses are fully customisable to your specific components, existing machines, and identified skill gaps. 📏

✅ Flexible Delivery: Training can be conveniently held at your facility, minimising operational disruption, or at our state-of-the-art headquarters in Aberdeen. 🏢

✅ Real-World Application: Unique opportunity to train directly with your own components, making the learning immediately relevant. 🏭

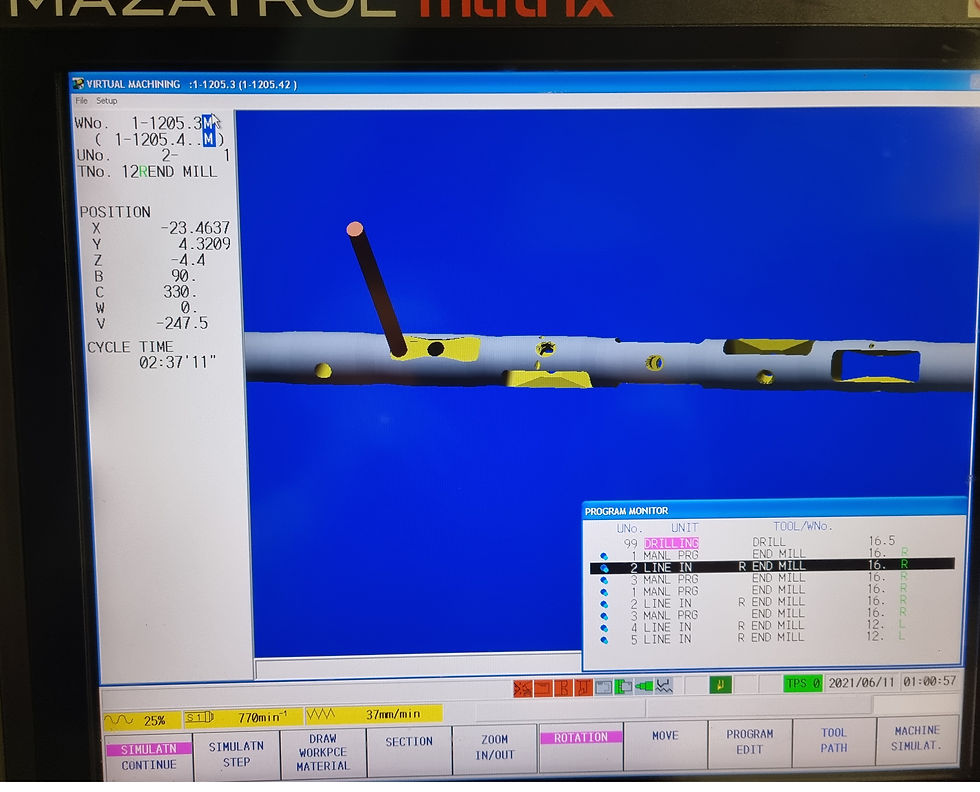

✅ Comprehensive Machine Control Support: Expertise across Fanuc, Siemens, and Mazatrol controls. If machines aren't available, we provide Fanuc and Siemens simulators for an immersive learning environment. 💻

✅ Expert Instructors: Learn from seasoned professionals with deep industry insight and practical shop-floor experience. 🧑🏫

Value-Added Inclusions: ✨

-

Essential Health & Safety protocols and industry best practices. ⛑️

-

Comprehensive Training Manuals for ongoing reference. 📖

-

Official Training Certificate upon successful completion. 📜

-

Dedicated Training Support post-course. 📞

-

A practical Company Gadget. 🎁

CNC Operator Training:

Master Machine Operation & Efficiency ⚙️

Duration: Customisable (Typically 3-5 days per course)

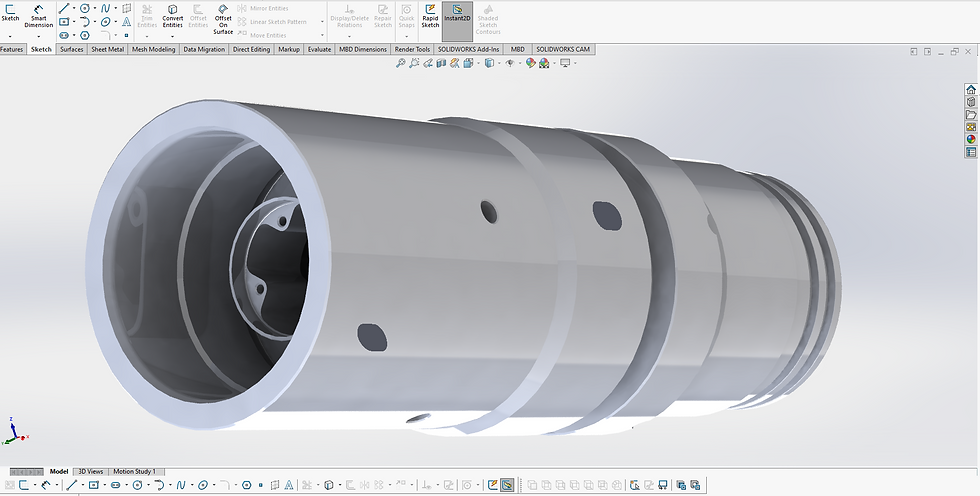

Our CNC Operator courses are designed for new operators or those looking to upskill in metals, plastics, or wood fabrication. 🌳 Get the fundamental knowledge and practical skills to confidently operate computer-controlled machines. 🖥️

Certification: CNC Machining Certificate upon successful completion. ✅

Upon completion of our CNC Operator training, you will be able to:

-

Set up and operate CNC lathes and/or mills with precision. ✨

-

Master tool loading, accurate offset adjustments (tool length, fixture), and efficient program execution. 📏

-

Identify and utilise operating controls on Fanuc, Siemens, or Mazatrol systems. 🎛️

-

Perform safe machine homing, start-up, and shutdown procedures. 🛑

-

Load and safely run new CNC programs. ▶️

-

Interpret engineering drawings and make necessary offset adjustments for tool wear and deflection. 📐

-

Maintain dimensional accuracy within specified tolerances.

Courses Offered:

Course Duration Key Skills Price (per attendee)

-

Beginner CNC Operator (Milling) 3 days Machine controls, tool offsets, basic G-code interpretation,

safety checks, workpiece loading, general milling operations. £595 + VAT 💰

-

Beginner CNC Operator (Turning) 3 days Lathe setup, Constant Surface Speed (CSS) control,

fundamental turning tool paths (facing, threading, grooving),

deflection adjustment. £595 + VAT 💰

CNC Programmer Training: Code for Precision & Productivity ✍️

Duration: Customisable (Typically 2-5 days per course)

Ideal for engineers transitioning into programming roles or experienced programmers seeking to optimise complex machining workflows. 🧠 Our programming courses equip you with the in-depth knowledge of G-code, M-code, and advanced programming techniques. 💡

Simulators available for Fanuc and Siemens controls if physical machines are not accessible. 🖥️

Upon completion of our CNC Programmer training, you will be able to:

-

Confidently write, edit, and optimise CNC programs using G-codes, M-codes, and conversational programming. 💬

-

Configure and program multi-axis operations (e.g., 3-axis, 4-axis, 5-axis milling/turning). 🌐

-

Implement advanced parametric functions and live-tool strategies for complex geometries. 📐

-

Develop efficient tool paths to maximise material removal and precision. 🚀

-

Interpret and apply engineering drawing specifications for precise program creation. 📈

Courses Offered:

Course Duration Control Level Price (per attendee)

-

CNC Basic Turning Programming (2-Axis) 2.5 days Mazatrol / Fanuc / Siemens Standard £745 + VAT 💰

-

CNC Basic Milling Programming (3-Axis) 3–4 days Mazatrol / Fanuc / Siemens Standard £1,100 + VAT 💰

-

CNC Advanced Milling (5-Axis Machining Centres) 5 days Mazatrol / Siemens Advanced £1,450 + VAT 💰

-

Multi-Axis Turning (Twin-Turret/Twin-Spindle) 3 days Mazatrol / Fanuc / Siemens Advanced £895 + VAT 💰

Please note: Prices listed are for individual attendees. For group bookings, on-site training at your facility,

or highly customised programs, please contact us for a tailored quote. 🤝

"We bridge theory and practice—empowering your team to maximise CNC productivity and achieve manufacturing excellence." 🌟

Ready to elevate your CNC capabilities? 👇

Should you have any questions, wish to discuss a customised training program, or

arrange a meeting, please do not hesitate to contact us. 📞

✉ Email: sales@mgctechnicalservice.com

📧 Call: +44 (0)7411 943 915 (8am–5pm BST) ☎️

MGC Technical Services Ltd | Aberdeen HQ | UK & EU Coverage

🌍 Precision Training for Precision Manufacturing 💎